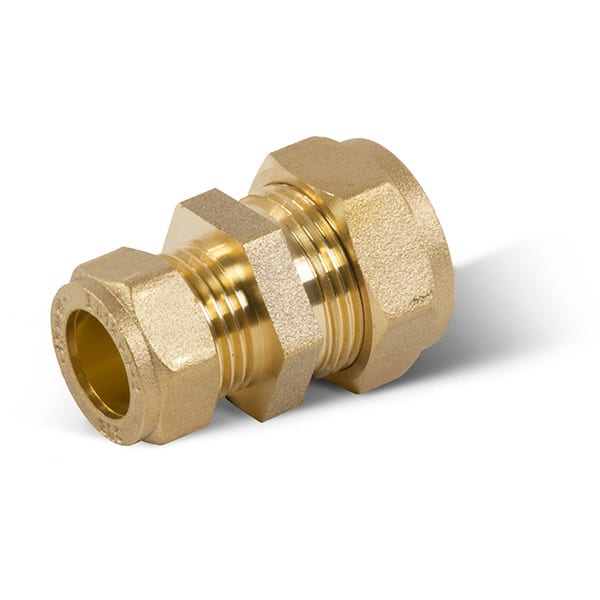

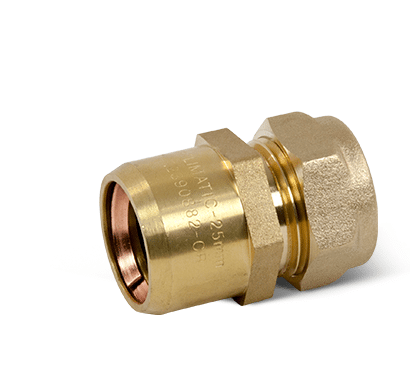

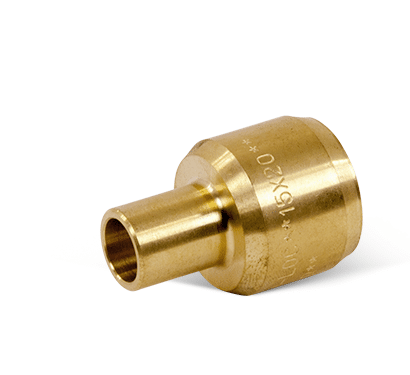

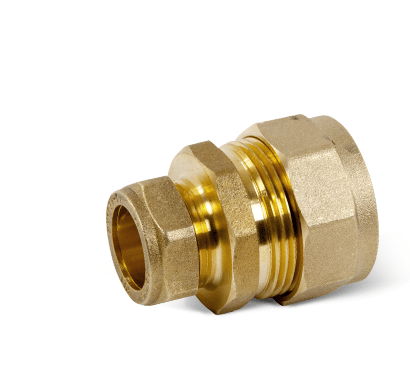

LEAD-LOC

Description

- LEAD-LOC

- Part size - (listed below)

- For use above ground only

- Can be used with hot or cold water

Our original LEAD-LOC compression fitting was developed to solve the problem of Joining lead pipe to copper. The nominal outside diameter pipe size of lead that this fitting is made for are listed below against the models available. Each LEAD-LOC Exceeds current water regulations for use on hot and cold water up to 80c. We use an internal O ring that keeps lead deformation to a minimum and holds up to 30bar and can withstand temperatures ranging from -35c to 250c we then use a carefully designed friction ring to stop entrapment of the thread and ads a positive stop to prevent overtightening. The unique grip ring technology feature gives uniform grip around the circumference of the lead, without de-forming the pipe or restriction the flow. LEAD-LOC will withstand end loads up to 200kg and is pressure tested to 30bar. For help with ascertaining the correct LEAD-LOC you require please visit our recourses link to find our installationpipe chart.

See our LEAD-LOC Range..

Are you a distributor? - get in touch, we’re here to help